- Deep Groove Ball Bearings

- Cylindrical Roller Bearings

- Single Row Cylindrical Roller Bearings

- Double Row Cylindrical Roller Bearings

- Four Row Cylindrical Roller Bearings

- Tapered Roller Bearings

- Single Row Tapered Roller Bearings

- Double Row Tapered Roller Bearings

- Angular Contact Ball Bearings

- Single Row Angular Contact Ball Bearings

- Double Row Angular Contact Ball Bearings

- Large Double Row Angular Contact Ball Bearings

- Four Point Contact Ball Bearings

- Spherical Roller Bearings

- Spherical Roller Bearings

- Barrel Roller Bearings

- Thrust Ball Bearings

- Single Direction Thrust Ball Bearings

- Double Direction Thrust Ball Bearings

- Self-Aligning Ball Bearings

- Thrust Roller Bearings

- Cylindrical Roller Thrust Bearings

- Spherical Roller Thrust Bearings

- Insert Ball Bearings

- Plain Bearings

- Spherical Plain Bearings

- Angular Contact Spherical Plain Bearings

- Thrust Spherical Plain Bearings

- Ball Bearings

- Roller Bearings

- Wheel Hub Bearing

- Magneto Bearings

- Auto Bearings

- Ball Mill Bearings

- Oil Drilling Rig Mud Pumps Bearings

- Oil Drilling Rrigs Mud Pump Bearings

- Conveyor Rollers Bearings

- Komatsu Construction Machinery Bearings

- Vibration Screen Bearings

Jinan BKLT Bearing Manufacture Co., Ltd.

Tel: +86-17564508291

WhatsApp: +86-17564508291

Wechat: +86-17564508291

Email: bofkbearing@sina.com

Address: Yandian Industrial Zoon, Liaocheng, Shandong, China

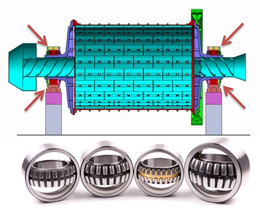

Ball Mill Bearings

Ball mill bearings' outer ring is suitable for the old insert's structure and size. Ball mill bearings have two structures. They are inner ring without ribs(inlet port bearings) and inner ring with ribs( outlet port bearings). Fixed end bearings are outlet port, traveling port bearings are in the inlet port. It slove thermal expansion and contraction problem. There are three center holes (locator holes ) in the outer ring of bearings, in every hole there's a 3-G2/1 oil filler hole. Ball mill bearings experienced twice temperature tempering, bearings will not out of shape in -40 degrees to 200 degrees.

1. Ball mill bearings changed from the old sliding friction to rolling friction, running resistance reduced and the resistance when start car reduce. It can save electricity energy;

2. Low running resistance and frictional heat, with special steel and special heat treatment in the manufacturing of bearings. It cancel the original cooling systems, save a lot cooling water;

3. Chanege the original light oil to little lubricants and greases, it can save a lot of light oil. For some big mill cancel the lubrication device in midheaven axis can avoid bearing burnt;

4. Improve the running efficiency, save the repair work anf time. Teo bearings can use 3-6 years;

5. The resistance when start car reduce, it extend the service life for motor, speed reducer and other equipments;

6. Ball mill bearings have fuctions of position, selfaligned, axial expansion and so on, totally meet the working condition for mills.

Two kinds, one is Split bearing devide the bearing inner ring into teo parts. Another is equiped the meddle of inner ring and midheaven axis with locking assemblies to fix bearings and avoid moving of bearings. It cantransform the bearing mill smoothly without manufacture of midheaven axis and reduce shut down. Bearings' service life are the same with original bearing mill. It reduce the cost during transform and using.

- Spherical Roller BearingsSpherical roller bearings have two rows of rollers, mainly take radial load, can also take axial load in any one direction. This kind of bearings have high radial load capacity, especially apply to the environments of heavy load or vibrate load, but they can't take axial load only. These bearings' outer raceway is spherical surface which contribute to aligning function, insensitive to misalignment of the shaft relative to the housing.

- Self-aligning ball bearingsThe outer ring of self-aligning ball bearings' raceway consist of two balls units composed by spheres, inner ring, balls and cage. The curvature center and bearing center line are the same. So the inner ring, ball and the cage can rotate around the bearing center. These bearings can be made into both opened and sealed. Self-aligning ball bearings have two structures: cylindrical bore and taper bore.

English

English Español

Español 中文

中文